Generating electricity using solar panels may seem nothing short of a miracle or magical like the wave of a wand. No moving parts. No generator. Just a blue or black panel that is exposed to sunlight.

If you are not familiar with the photovoltaic effect or the working of a solar panel, you cannot be faulted for thinking this way.

If you go solar shopping without any prior knowledge, you will be overwhelmed by the numerous permutations and combinations of choices available to you. The material used in the solar cell, the choices in the quality of protective glass sheet, the material and compilation of framework, the selections in the back sheet, and diverse options in bypass diodes and connectors can confound and confuse you.

If you want to join the trend and “go solar”, you can get the best out of the solar panel systems by understanding its basics. Each one of your choices will impact the efficiency, longevity, and utility of the solar panel systems you are installing.

This article tries to explain the renewable energy technology that goes into the manufacture and working of a solar panel. Here, you will find the 6 main solar panel components explained in detail, along with various choices available in them.

How does solar power work?

The photovoltaic effect is the basic principle behind this magical phenomenon. When sunlight is incident on a semiconductor material like silicon, it generates voltage or electricity. Here is a simple explanation of how it happens.

A p-type (with excess holes) and n-type (with excess electrons) semiconductors are sandwiched together to form a p-n junction. Though the material as a whole remains electrically neutral, near the p-n junction, an electrical field is formed, when electrons jump from n-side to p-side. If an external connection is made to bring the electrons from the p-side back to the n-side, a continuous flow of electrons in a single direction can be maintained. The flow of electrons constitutes electricity.

In its normal state, electrons on their own won’t jump across to the p-side. This is where solar energy helps.

Sunlight is composed of photons or small packets of energy. When sunlight falls on a semiconductor material (on the n-type semiconductor), the energy is transferred to the electrons in its atoms. The energized electrons break free from the atomic bond and make the jump across the p-n junction.

For more on this topic, see our article on how do solar panels work which goes into more detail about how the solar panel produces electricity.

What is a solar cell made of?

Solar cells or photovoltaic cells or simply PV cells are made using silicon crystalline wafers. Depending on the technology used and the manufacturing process, silicon wafers differ in composition, quality, and efficiency. It can be monocrystalline, polycrystalline, or the in-between cast monocrystalline silicon wafers.

The raw material used is quartzite which comes from quartz sandstone rock. Also known as silica sand, quartzite is combined with carbon at high temperature in an arc furnace to form metallurgical-grade 99% pure silicon. This is converted into polysilicon using a chemical purification process known as the Siemens process.

Polysilicon is doped in boron or phosphorus to make p-type and n-type silicon semiconductors.

The doped silicon undergoes the Czochralski process to convert it into a single monocrystalline crystal or ingot. The doped silicon is melted and recast into rectangular blocks to form polycrystalline silicon. The manufacturing process of cast monocrystalline cells is similar to that of polycrystalline silicon cells.

Then, there is the cheapest among the solar cells – thin-film cells. Easiest and least costly to manufacture, thin-film cells are made from different materials. The three most common photovoltaic materials used in thin-film cell manufacture are Amorphous Silicon (a-Si), Cadmium Telluride (CdTe), and Copper Indium Gallium Selenide (CIGS).

A layer of photovoltaic material is sandwiched between a layer of conductive material like aluminum and a thin protective layer of high-quality glass or plastic in a thin-film solar cell.

What is a solar panel made of?

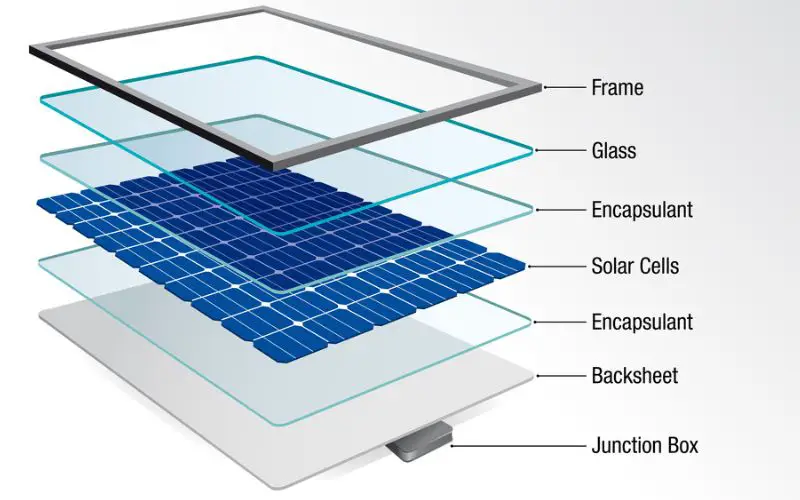

A solar panel is an arrangement of solar cells assembled with a protective glass panel in the front, a back sheet for protection and insulation, and lamination with EVA films on either side for waterproofing and shockproofing in an aluminum frame with a junction box and connectors to complete the electrical connection.

The entire arrangement is assembled with high accuracy levels in advanced manufacturing units. Here’s the solar panel components list.

6 key components of a solar panel

- Solar cells

- Protective glass panel

- Lamination with EVA film

- Polymer back sheet

- Aluminum frame

- Junction box

The quality, efficiency, and longevity of a solar panel depend on the individual solar components chosen to form the solar panel.

1. Solar cells

As explained above, there are choices available in solar cells that vary vastly in efficiency and price. The monocrystalline cell is the best in efficiency but is also the costliest because of the difficulty involved in the procurement of the ingot. Cast mono and polycrystalline cells come next in efficiency and cost. Thin-film cells are the cheapest and the lowest in efficiency levels.

The choice of the type of solar cell is often based on the ground conditions and other limitations like the availability of sunlight. If there is limited space for installation, monocrystalline cells will give you the best output. If there is plenty of sunlight year-round, polycrystalline cells would suffice. When the surface is curved or in places where other solar cells cannot be installed, thin-film cells can help you capture the solar energy.

Most solar panels have 60 solar cells arranged with busbars connecting them in series to produce a voltage of 30-40 volts. The commercial solar panels may have 72 or more solar cells to generate a higher voltage.

Related:

2. Protective glass panel

The purpose of the glass panel is to protect the solar cells from extreme weather conditions, at the same time allowing maximum absorption of sunlight. As the solar panel is exposed to the elements 24×7, unless good protection is provided, it will not last long.

The solar panel has to survive torrential rain, severe heat, heavy snow, and powerful hailstorms. It should be able to withstand falling tree branches or any other heavy objects. Besides, it also has to be protected from dust, dirt, and debris such as leaves and bird droppings.

You should also read our guide on how to protect solar panels from hail if you live in an area with frequent hailstorms.

The glass used in a solar panel needs to be thick and strong enough to withstand high loads and extreme temperature variations. High-strength tempered glass of at least 3-4mm thickness is the minimum requirement. The IEC has set a minimum standard impact test that involves surviving the impact of 1-inch hailstones hitting the panel at 60mph.

Tempered glass is preferred over the standard glass as it will not shatter into sharp jagged pieces in the event of breaking.

However, care must be taken to ensure that the glass doesn’t prevent sunlight from reaching the solar cells. High levels of transparency and low levels of reflectiveness are desirable in the glass panel. Glasses with low iron content have higher levels of light transmission. Adding an anti-reflective coating to the rear side of the glass panel can help in reducing its reflective properties.

3. Lamination with EVA film

EVA or ethylene-vinyl acetate is a special polymer created specifically for high levels of transparency. The basic function of the EVA film is to hold the solar cells and their wiring together and offer waterproof and shockproof protection.

As the solar panels remain out in the open during all weather conditions, each additional layer of protection it has against moisture and breakage helps in prolonging its lifespan. Laminating the solar panel arrangement is the best way to achieve this level of protection.

To ensure the highest level of protection for the solar cells inside, the film used for lamination has to be chosen with care. Durability and tolerance of temperature variations and humidity are the main criteria.

4. Polymer back sheet

The back sheet acts both as a protection against water ingress and moisture seepage as well as as a barrier for electrical insulation and physical protection. The material chosen for the back sheet may be any kind of plastic or polymer. PET, PVF, and PP are the most common. Each one of these offers diverse levels of protection, resistance, and stability.

If you are looking for hi-end protection for your solar panels, you can choose one with a glass panel as the back sheet. Dual glass panels offer much better protection than plastic or polymer back sheets. Often solar panel manufacturers offer longer warranty periods for such solar panels.

5. Aluminum frame

Just like other parts of a solar panel, an aluminum frame also has a role to play in protecting the panel from damage and ensuring its longevity. A strong frame can help protect the edges of the insulating EVA layer from breaking, bending, or fraying. The frame offers the panel a solid shape and structure for easy handling during transportation and installation. It also helps to mount the solar panel on a solid structure and keep it in position day in and day out.

The aluminum used in the frame will ensure that it doesn’t add much weight to the solar panel and at the same time is strong enough to withstand the rough and tumble of handling and severe weather conditions.

Aluminum frames may come in silver or anodized black colors. The corners may be clamped or pressed together or maybe screwed in. The quality of aluminum used also can make a difference in the protection level.

6. Junction box and connectors

A junction box is attached to the rear side of the solar panel, offering points for electrical connectivity. It performs the vital function of linking with other solar panels as well as with other components of solar power systems like inverters.

The waterproofing of the junction box is crucial as it is exposed to weather but cannot allow ingress of dirt and moisture. The waterproof rating of IP65 is the most desirable for the junction box, though you may find ones with IP67 or IP68 as well. IP65 ensures complete protection against dust and low-pressure water jets.

Bypass diodes: These are an integral part of the junction box. They can prevent the backflow of current when cells are not generating current. Diodes ensure that current flow is in one direction from the solar panels to the inverter. In the latest panels, diodes are also used to reduce overheating and increase the lifespan of panels.

MC4 Connectors: Just as the junction box requires high levels of waterproofing, the connectors also need to be resistant to weather and moisture for the solar panels to function efficiently and last longer without breakdowns or damage. Multi-Contact 4mm connectors are robustly built, UV resistant, have minimal resistance, and can maintain a good connection.

Related: Solar Panel Maintenance Checklist

Assembling solar panels

Precise positioning of components and high levels of accuracy is needed while assembling solar panels. To ensure this, assembly of solar panels is done in fully automated manufacturing establishments with robotic equipment and high-end sensors.

The manufacturing facility must maintain excessive levels of cleanliness to avoid contamination. At various stages of manufacturing, the solar panels are inspected using optical sensors to ensure correct alignment and no damage. The final product is subjected to various quality control tests including flash testing and electroluminescent testing.

Bottom line

As technology is improving and the prices dropping, the “going solar” trend is catching on. It is offering us a chance to save the environment, albeit in a small but significant way.

Before jumping on the renewable energy bandwagon with solar power, gathering more information about the various aspects of solar panels is desirable as it would help us make better choices.

Recommended Reading: